|

|

| Norm Voelzow |

|

|

|

| ALI 3.710USB Rotalign® Pro PC Simulation Program (click) |

|

|

Spacer

Shaft Tolerances Explained

___________________________________________________________

|

Question:

From Sim Sze Tung – Singapore China. The tolerance card for spacer shaft

is in mils/inch. Does this per inch refer to spacer shaft length or coupling

diameter and, is this a gap or offset reading?

Explanation:

Spacer

Shaft Tolerances

To apply Alignment Tolerances to a Spacer Shaft

(Jackshaft, Spoolpiece etc.) we multiply the length of the Spacer Shaft in

inches times the speed related Spacer Shaft tolerance from the tolerance table

shown below. This will give us a tolerance to be used to check against the

actual offsets, both vertical and horizontal,

that the Optalign® or Rotalign® will show us at each coupling center

in the Coupling Mode. Note: Offset is the amount

the two centerlines are separated

(offset) from each other at any specified point. Normally, offset is measured

at the center of the coupling(s) which is where

the torque is transmitted. Typically we express alignment related offsets

as VO for Vertical Offset and HO

for Horizontal Offset.

For

example, using a 60" Spacer Shaft which

rotates at 1,800 RPM, we multiply the Spacer

Shaft Length of 60" by the speed related Spacer Shaft tolerance

of 0.6 mils/in. which results in an offset tolerance

of 36 mils. This tolerance will be used to check

the actual offset the Optalign® or Rotalign® will show us in the Coupling

Mode and must be checked at each coupling center!

|

|

| Tolerance Table (click) |

|

|

The

Optalign® or Rotalign® calculates the

actual offset between the Stationary Machine

and M.T.B.M. (Machine To Be Moved) centerlines,

using the dimensions you entered. Also, the Optalign® or Rotalign®

can show us the relationship or offset between Stationary Machine and M.T.B.M.

centerlines anywhere along these centerlines.

Even if you are using the older Optalign® IR (invisible beam) or V system

you can still compare two points or both ends of the Spacer Shaft as shown

below! (Note: To do this with the older Optalign®

IR / V we need to change the dimension from Prism to Coupling Center

after getting the results for the one end!)

|

You

can see from this example illustrating the actual Vertical

Offsets that by checking the tolerance at both coupling centers and

correcting the alignment, we are actually controlling

the angularity between the two machines

centerlines and possibly preventing a catastrophic

failure! With Spacer Shafts we do not

need to look at both Gap and Offset as we do with Short Coupled machines since

once we achieve Tolerance on a Spacer Shaft alignment the angularity will

be very small and well below Tolerance.

Note

1: For Spacer Shafts under 6" in length, we would use the Short

Coupled Tolerances which are found under the headings of Gap and Offset in

the tolerance table shown above.

Note

2: Use OEM or in-house tolerances if available.

Have

a Grand Day!

Norm & Bev Voelzow • Voelzow & Company, Inc,

©

Copyright 1997 Voelzow & Company, Inc. Wingate, North Carolina

|

Two

Commonly Asked Soft Foot Questions

___________________________________________________________

|

Question

#1: What does the Optalign® or Rotalign® show us in the Soft

Foot mode?

Answer: Shaft movement

only — not foot movement and

not soft foot correction!

Question

#2: Why doesn't the Optalign® or Rotalign® show the actual

Soft Foot correction?

Short

Answer: They are not designed to!

Long

Answer: We do not enter a dimension from the base to the centerline

of the motor shaft nor do we enter an inside dimension (side to side) of the

feet! In order for any computer to "guess" at the actual soft foot

fix, the computer would need the front to back foot dimension plus these additional

dimensions. Notice I said "guess"!

How many times do we have perfectly flat feet and a perfectly flat base —

never or almost never! If we want a computer to calculate the soft

foot correction — we would need to supply the motor front to back foot

dimension, the dimensions mentioned above and the following information:

- Is

the foot flat or bent? If bent, is it bent up or down — towards the

outside of the motor;

is it bent up or down — towards the front or back of the motor; or

a combination of both?

- Is

the base warped? If warped — which way?

- Is

the base solid or corroded or flimsy?

- Are

you using a stack of shims, a few shims or no shims when measuring soft

foot?

-

Are the shims bent? Are the shims dirty?

-

Is there dirt under the motor feet?

-

Etcetera, Etcetera, Etcetera !!!

Get

the picture? That is a lot of information to try to get just to

have a computer still "guess" at our

Soft Foot correction! We recommend that you work on the foot that the Optalign®

or Rotalign® displayed as having the most movement — using

feeler gages! Fix that foot and recheck

all of them again! (Some use shim stock to determine the correction but may

not notice the taper!)

Here

is another picture for you. This triangle graphically shows you how the Optalign®

or Rotalign® is calculating the movement of the shaft centerline. The

base of the triangle is where the motor centerline is with the all of the

feet tight. The Hypotenuse is the motor centerline with one foot loose! Interesting

— I think so!

|

This

is the Angle measured by the Optalign®,

Masterlign® or Rotalign®.

|

| This

is the number displayed on the Optalign®, Masterlign®

or Rotalign® screen which is Shaft Movement

at the shaft centerline and NOT Soft Foot shim correction!

|

This

is the Front to Back foot dimension entered

by you in the Optalign®, Masterlign® or Rotalign® dimension

screen.

|

The

number displayed on the Optalign® or Rotalign® screen in the soft

foot mode is based upon a movement of the shaft — PERIOD!

Again; Shaft movement only — not

foot movement and not soft foot correction!

Go to the foot with the most movement and use feeler gages to determine the

correction. With feeler gages you can also determine if there is any taper

indicating a bent foot. Bent feet or rolled/bowed bases usually require step

shimming. Don't try to short cut by "side stepping" soft foot! There

are no short cuts with soft foot — just perseverance, determination

and finally skill! Good Luck, Norm Voelzow

©

Copyright 1997 Voelzow & Company, Inc. Wingate, North Carolina

Optalign®

& Rotalign® are registered trademarks of Prüftechnik Dieter Bush

AG of Ismaning, Germany

|

___________________________________________________________

|

We

have written the above Laser Tip about Soft Foot

because checking Soft Foot with a laser is so

misunderstood by so many people!

We have explained what the laser "sees"

in the Soft Foot mode since 1986, shown 1,000's of people in classes and in

the field and we turn around and people go back to assuming

the lasers show the Soft Foot shim correction!

Go figure!

Do

yourself a favor and don't complicate

Soft Foot! Use the laser to ferret

out the problem foot or feet and then use your head and a set of feeler gages

to "really see" exactly what is going

on under that foot!

Remember,

I never said that doing Alignment or correcting

Soft Foot was easy with the laser but I always

have said that a laser made both much easier!

Note:

This Laser Tip is two - sided with the Typical Causes

Of Soft Foot graphics by Bev Voelzow shown on the reverse side! You

will need to click on the "Two Commonly Asked Soft

Foot Questions" PDF icon above to see Bev's work!

Have

a Grand Day!

Norm & Bev Voelzow • Voelzow & Company, Inc,

©

Copyright 1997 Voelzow & Company, Inc. Wingate, North Carolina

|

Recent

Laser Tips for Download

___________________________________________________________

|

___________________________________________________________

|

|

|

|

| In the USA - Need a Calibration Check? (CLICK) |

|

|

|

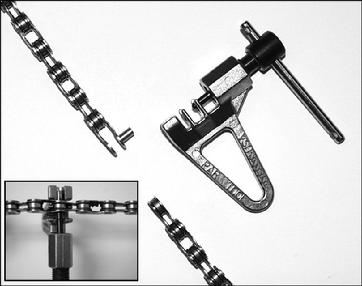

Compact

Chain Tool

___________________________________________________________

|

|

| VCT-5 Compact Chain Tool - (click) |

|

|

The

VCT-5 Compact Chain Tool facilitates shortening

or lengthening bracket chain without damaging the existing chain or special

ends!

VCT-5

Compact Chain Tool . . $21.00 each

(Chain

not included)

VCT-5

set Compact Chain Tool w/ two 30" lengths of extra chain . .

$45.00 per set

Important:

Do not insert the extra chain needed by taking apart the installed master link(s)

but, using the VCT-5 Compact Chain Tool, skip over

a link or so from the master link and

insert at that point. Most of us will break the lightweight European master

link – especially Norm Voelzow (me)!

We

accept, Master Card and Visa! Call 704-233-9222 or request

a Quotation by email.

|

VCT-5 Compact Chain Tool Flier |

Sunlight

and The Lasers

___________________________________________________________

|

Sunlight

and The Lasers

Occasionally

we have had customers tell us that they thought that Sunlight

was preventing the laser system from taking measurements when the machinery

being aligned was located outdoors and that they

wanted a more powerful laser! We explained that a more powerful laser is not

the answer but in fact they were getting interference from direct Sunlight

or too much reflected light off of other equipment!

Even

though all of the Pruftechnik laser systems filter out all light except for

670nm frequency used

by the Rotalign and Optalign

lasers – the Sun generates all of the frequencies

of light! Another important point is the fact that the Rotalign and Optalign

lasers power are designed and rated as Class 2 lasers - for Safety

reasons!

Even

if the factory went to the next class laser, Class 3, you can still can experience

the direct or reflected Sunlight issue as the photocell

in the Rotalign Receiver or Optalign Transducer will still see a lot of the

lasers 670nm frequency from the Sunlight.

Important: Anything above a Class 3 laser could not

be used in the open because of the chance of an individual being blinded.

Here's

another way to look at the Sunlight issue. Imagine

that you were using a camera mounted where the laser's Receiver or Transducer

is and were trying to take a picture of the other component with the Sun

in the background. . . . . ! You would have the same problem with the

Sunlight unless you had a hood on your camera's

lens – get the picture!

When

doing alignment outdoors you most probably will need to use a Sunshade!

But, not just anything you have laying around as you must be careful not to

put any excessive weight on the Rotalign Receiver or Optalign Transducer –

and that is why the older Sunshade we had previously

was so light but fragile!

In order to overcome this inconvenience and fragility the US Pruftechnik Distributor,

Ludeca, developed the L 660 Sunshade which helps

the user to overcome the Sunlight issue outdoors

during the initial set-up and when measuring! Much like a camera with the attached

hood used on large diameter lenses – this Sunshade

is designed for Rotalign style Receivers and Optalign style Transducers as shown

in the photos to the right.

If

you are using your laser system outdoors we recommend you get a Sunshade!

You can order an L 660 Sunshade from Nils

Heilemann at Ludeca (305-591-8935) – please tell Nils that

Norm and Bev said hello - thanks!

|

|

| L660 Sunshade mounted on a Rotalign Receiver (click) |

|

|

|

| L660 Sunshade mounted on an Optalign Plus / smartALIGN Transducer (click) |

|

|

___________________________________________________________

|

Hello,

If

you want more information, wish to comment on a Laser

Tip, request that a Laser Tip be made

or request a previous Tip - please

use the Request Form link below, call us at 704-233-9222 or send

us an email.

Thanks

- Norm & Bev

Laser

Tips © Copyright 1997 Voelzow & Company, Inc. Wingate, North Carolina

|

_____________________________________________________________________

Links

The

following are some very good links for you to visit and well worth your time!

Just click on the graphic and be sure to check back as more great links will

be added very soon. Norm

_____________________________________________________________________

|

|

|

| We ship daily by the Big Brown truck on orders received as late as 5:30 pm EST! |

|

|

|

Untitled Document

© Copyright Voelzow & Company, Inc. - Wingate, North Carolina USA.

Reference

the Digital Millennium Copyright Act Of 1998.

Top

Gun®, when used with Laser Shaft Alignment, is a registered trademark

of Voelzow & Company, Inc Wingate, North Carolina USA.

Note:

We have not given anyone or any company

permission to use any text from our website on their website or in printed material!

|

|

| Send E-mail |

|

| |

|

Top

of Page

___________________________________________________________

|

|